Compressors

Air Compressors

DXP Natpro offers a complete line of oil-free and oil-flooded air compressors using rotary screws or reciprocating technology. All complemented by a complete range of air treatment and other system components to help you optimize efficiency, reliability, and overall performance. Add to that our expertise in system design, turnkey package capabilities, and maintenance services, we are positioned to provide the best air solutions to suit your specific plant needs.

Air Compressor – Screw (oil flooded and oil free) and Reciprocating

Quincy

Kobelco

Gas Compressors

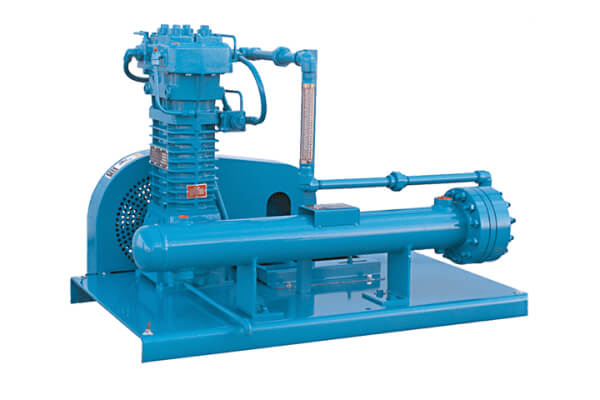

DXP Natpro offers reciprocating, liquid ring, diaphragm, and centrifugal gas compressors up to 4000 HP. Our solutions can be found at well sites, gas plants, vapor recovery units, refineries, petrochemical plants and most recently Carbon Capture facilities. Our gas compressors are commonly applied on sweet and sour natural gas to difficult gases such as Hydrogen where the gas must be fully contained in the compression chamber. Complimented by our local capabilities in package design, fabrication, and aftermarket services, we are positioned to provide gas compression solutions to meet your most demanding application needs.

Gas Compressors

Sundyne – LMC, Pinnacle, PPI

Gardner Denver – Garo, Nash

Blackmer

Quincy